Installation & Commissioning

FECC specializes in installation of heavy equipment like Compressors, Pumps and Turbines at both Offshore and Onshore sites as per OEM guidelines.

One of the most critical steps of installation is Alignment of the equipment with the driver.

Our skilled team ensures that the alignment of the driven shaft and driving shaft is the same as the design value using Laser Alignment tool / dial indicators.

Our team is also well versed with all the other steps like – Lube oil system maintenance, electrical and instrumentation hook-up, auxiliary piping / valve connections, priming, and site testing and commissioning of the equipment.

Borescope Inspection

During inspection, there are many hard-to-reach areas which are not visible and require certain flexible mini sized camera lens to check for damages.

FECC has “Olympus” Japan make Borescope which provides Real-time monitoring and enables easy inspection of any area with clear high-resolution images.

Usually, Borescope is used for Rotor inspections, Pipe inspections, Weld inspections, etc. The lens is easily flexible and is remote controlled so that it can be guided through the Impeller vanes, Pipes, etc. to check for any damages.

We provide Borescope inspection services to OEMs and End-Users.

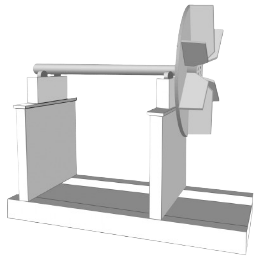

Balancing

Dynamic Balancing is one of the most important aspects during overhauling / maintenance of any rotating equipment. Accurate balancing ensures minimal vibration of the equipment. This is achieved either by adding or removing weight from the rotating component until the unbalance is under tolerance.

FECC has an in-house SCHENCK make Balancing machine. We specialize in Balancing of Compressor rotors, Pump rotors, Power Turbine (PT) rotors, Blower rotors as well as Turbochargers, etc.

We provide Dynamic and static balancing services to OEMs and End-Users.

Casing Repair

Pump / Compressor casing is a crucial part which after some years of operation starts deteriorating and wear / corrosion are usually observed.

FECC specializes in Casing repair with the help of welding and machining according to OEM guidelines. We use methods such as CMM to check the concentricity and planarity and thus rebuild the surface to the design requirements.

High pressure Hydrotesting

FECC has an in-house facility for Hydrotesting upto 430 Kg/cm²

Usually after repair of major parts, hydrotesting is required to check if there is any leakage.

We perform Hydrotesting as per OEM standards and requirements.

Electrical run-out correction

Electrical run-out of any rotating equipment should be under tolerance specified by OEMs. This is done on the probe track area of the shaft which ensures accurate vibration sensing of the shaft by the probes.

FECC can do the electrical run-out correction of the shafts as per OEM guidelines.

Fabrication of emergency spares

During overhauling, there are some emergencies that can arise and are not anticipated. In these cases, spares or consumables are required on urgent basis.

FECC can fabricate / manufacture such spares as per OEM requirements.

Shaft Straightening

FECC specializes in correction of mechanical run-out by performing Shaft straightening.

While performing Shaft straightening, we take utmost care and make sure that no stress concentration or grain deformation is caused on the shaft.